| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : NPACK

Model Number : NP-LC

Certification : CE

Place of Origin : China

Cap Dimension : Φ35-65mm

Capping wheels : 6 to 8

Capping Accuracy : Capping Yield>=99.9%

Conveyor : 2M

Driven Method : Electric

Feature : High Speed

Gas Consumption : 0.5M/0.8MPa

Guarantee : 1 year

Machinery Test Report : Provided

Noise : ≤75dB

OEM : yes

Inventer : Danfoss

Power Consumption : 1.5KW

Usage : screw Caps

The six-spindle wheels capping machine, operating seamlessly in a straight-line configuration, is equipped with a robust C-chute mounted on the head. The durability of this model, attributed to its heavy-duty design, not only minimizes maintenance requirements but also enhances productivity and flexibility to a significant extent. It is adapt for a variety of caps, including spindle screw caps, locked caps, spray caps, and more. The applicable caps can be made of metal or plastic.

| NAME MODEL | NP-LC Automatic linear spindle capping machine |

| Capacity | 0~200b/m(subject to bottles and cap size) |

| Bottle and cap diameter | Φ10~120 subject to samples |

| Bottle Height | 40~380mm |

| Spindle capping machine dimension | L1060*W896*H1620mm |

| Voltage | AC 220V 50Hz |

| Power | 1600W |

| Weight | 500kg |

|  |

|  |

PLC-controlled non-contact torque monitoring for precision.

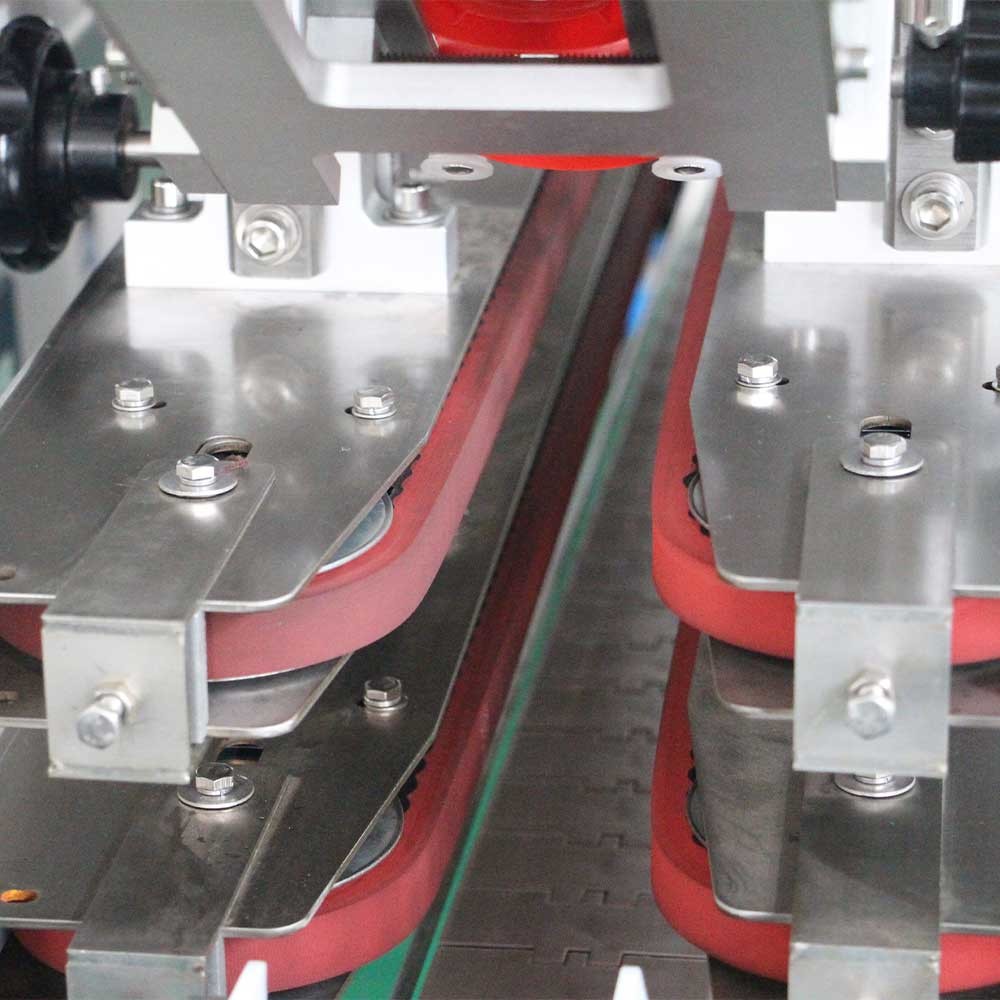

Stainless steel gripper belts assembly with pulleys and bearings for durability.

Stainless steel clutches for enhanced performance.

Pneumatic clutches for efficient operation.

Quick changeover package, inclusive of counters and scales, facilitating swift transitions.

Power height adjustment for added convenience.

Capper guarding package equipped with safety interlocks for enhanced safety measures.

NEMA 4 controls and switches to meet specific electrical enclosure standards.

Enhanced corrosion resistance coatings for extended longevity.

1. Q1: What is a 6-Wheel Capping Machine and what is its main function?

A: A 6-wheel capping machine is an automated packaging device equipped with six independent capping heads. Its primary function is to automatically and accurately screw caps onto corresponding containers at high speed, enabling efficient and continuous production.

2. Q2: What types of caps and bottles is the 6-wheel capping machine suitable for?

A: The machine has a wide range of applications:

Cap types: Plastic caps, metal caps, spray caps, tamper-proof caps, pump heads, etc. (requires compatible capping heads).

Container types: Plastic bottles, glass bottles, jars, and other round-section containers.

3. Q3: What is the basic workflow of the machine?

A: The typical workflow includes:

4. Q4: How is the cap tightness (torque) set and ensured?

A:

Setting: The target torque can be directly set on the touch screen (servo-controlled).

Ensuring Consistency: The servo motor controls the torque precisely. During the capping process, the head automatically stops rotating or slips once the preset torque is reached, ensuring uniform tightness for every bottle.

5. Q5: Are there special requirements for cap feeding?

A: Yes. A stable cap supply is essential for smooth operation.

Requirements: Caps must be sorted and oriented using a vibrating plate or elevator and delivered continuously and smoothly to the capping heads.

Potential Issues: Complex-shaped caps, burrs, or overlapping caps may cause jams or missing caps, reducing efficiency.

6. Q6: What are the possible causes of loose or inconsistent capping?

A: Possible reasons include:

|

|

NP-LC Fully Automatic Spindle Capping Machine With Cap Feeding Elevator Spindle Capper Images |